Mobile Audit & Calibration

Overview

When was your tooling last inspected?

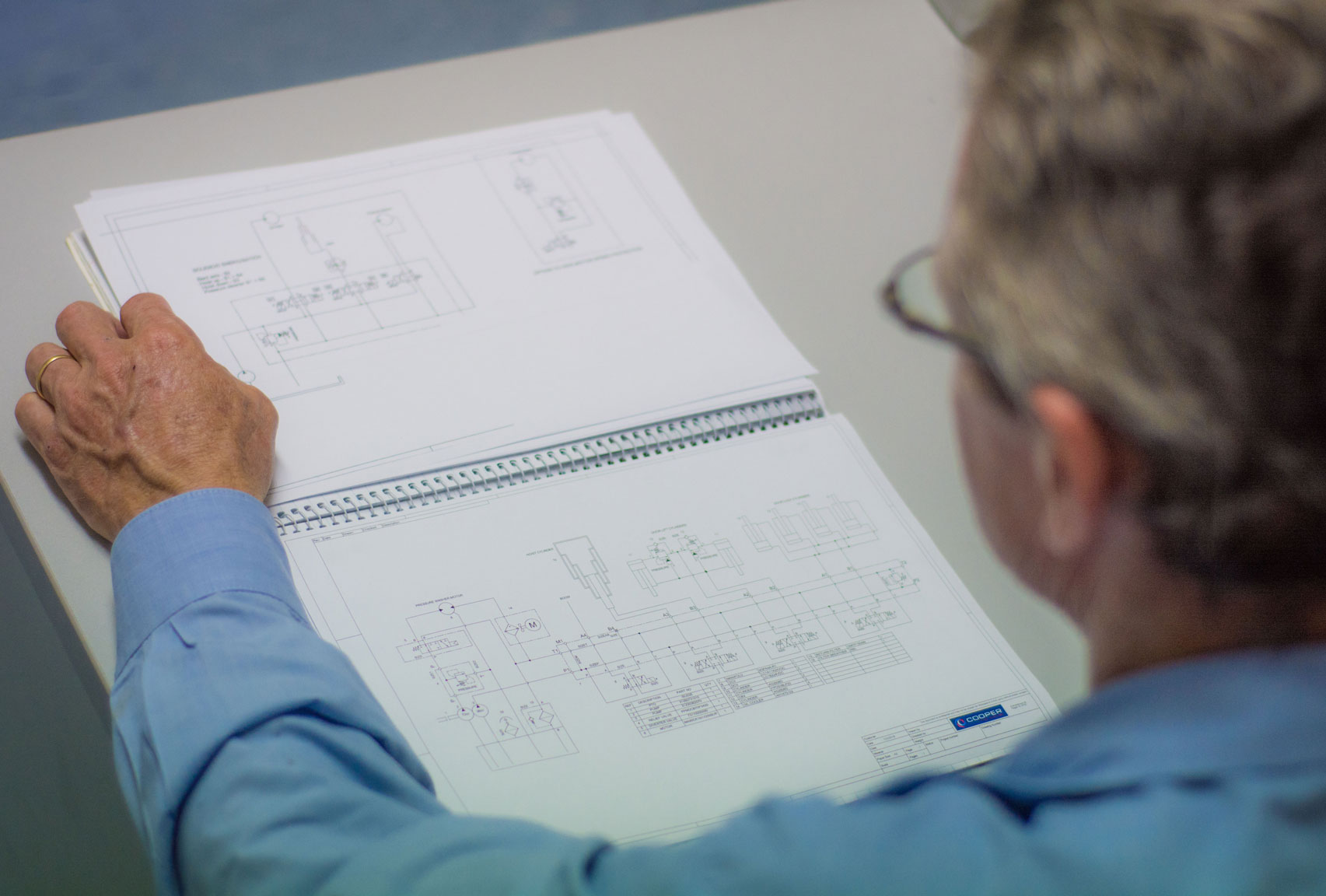

Safety is paramount when using high force hydraulic tooling as poorly maintained equipment can expose operators to many hazards in the field. Our mobile audit team can assist by identifying worn out, unsafe and damaged tooling.

Cooper Fluid Systems, in partnership with Enerpac, are proud to offer our customers onsite audit, testing and calibration of all hydraulic and pneumatic torque tools. Our fully trained and qualified service technicians carry out a wide range of preventative and breakdown maintenance, as well as quarterly safety audits for all 700-bar hydraulic tooling (cylinders, hoses, pumps, jacking, bolting etc.). We have audit vehicles available to service Queensland, Western Australia and New South Wales.

Our Capabilities:

- Calibration of Hydraulic Torque ToolsCalibration of Hydraulic Torque Tools – capacity up to 38,000 Nm.

- Calibration of Pneumatic Torque Multipliers (Guns)

- Inspection and servicing of PowerLock and PowerRiser heavy-vehicle jacks

- Inspection and testing of 700bar Hydraulic Cylinders, Pumps and Tooling

- Safety Training in the safe operation of Enerpac equipment

- Quarterly tooling audits, with colour-coded periodic tagging

Manufacturers Brochures